How to assemble the ESky CNC alloy head for King and Belt-CP. |

Parts required:

1. Main Blade Clamps

2. Alloy Rotor Head

3. Alloy Swash Plate

4. Alloy Washout Assembly |

|

|

|

1. Firstly, you'll need a philips screwdriver and 1.5mm

allen driver. Also, thread lock and CA glue for use where neccesary.

|

|

2. In addition to the alloy components you will need

the control linkages from your original rotor head. Its best to work

on a clean, clear surface. |

|

|

|

3. Insert the flybar holder through the head and attach

with the 2 silver screws. Use thread lock on these. Ensure the screw

hole is on the right side.

|

|

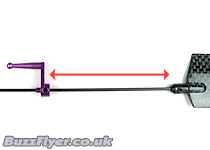

4. Screw and slide one of the alloy levers along your

flybar. The length between paddle and lever should be about 56-59mm

with the paddle fully screwed in.

|

|

|

|

5. Push the flybar through the flybar holder, attach

the other lever and paddle. Centralise everything and tighten - ensuring

the levers are level with the paddles.

|

|

6. Assemble the components of the pitch levers...

|

|

|

|

7. and attach them to the flybar holder in the direction

shown here.

|

|

8. Assemble the bearings and washers as shown here, with the smaller holed washer on the inside.

|

|

|

|

9. The collared washer should have its raised edge towards the bearing. The spacer shim washer should be left out if the blade clamps don't move freely once tightened.

|

|

10. Insert the rubber o-rings and slide the shaft holder

into the head.

|

|

|

|

11. Pop the plastic linkages onto the levers and insert

the shaft through shaft holder. Attach the second blade clamp and tighten

both shaft end screws.

|

|

12. The head is fixed to the main shaft with a pin and

grub screw.

|

|

|

|

13. Insert the pin here, and fit the grub screw using

thread lock.

|

|

14. Slide the washout assembly up the main shaft and

onto the two locating pins.

|

|

|

|

15. Slide the swashplate up the shaft and attach to the

plastic washout linkages.

|

|

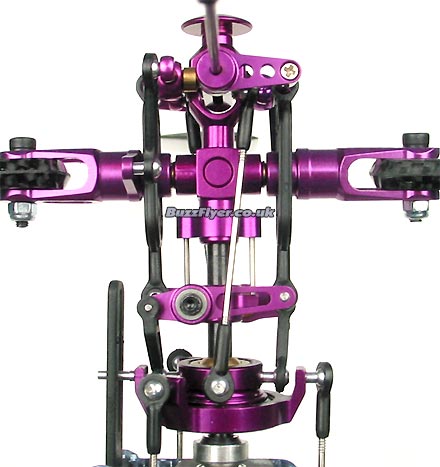

16. Finally connect the control linkages to the head,

as shown in these pictures.

|

Paddle side view:

Blade side view:

|

|

When installing onto the heli; note it is important that all the parts are

free and do not bind. If this is the case, loosen where needed, making sure

thread lock is re-applied to secure the metal to metal bolts and screws.

If they bind, this will cause battery drain and possible damage to the servos.

I would recommend building the head onto a new main shaft - removing the

old shaft and head for use as a guide of direction and alignment.

Also note: you will have to re-setup the blade pitch once the installation

is complete.

|